Products

As a crucial piece of equipment in steel production, the continuous casting machine continuously casts high-temperature molten steel into billets with specific cross-sectional shapes and size specifications, greatly improving production efficiency and steel quality.

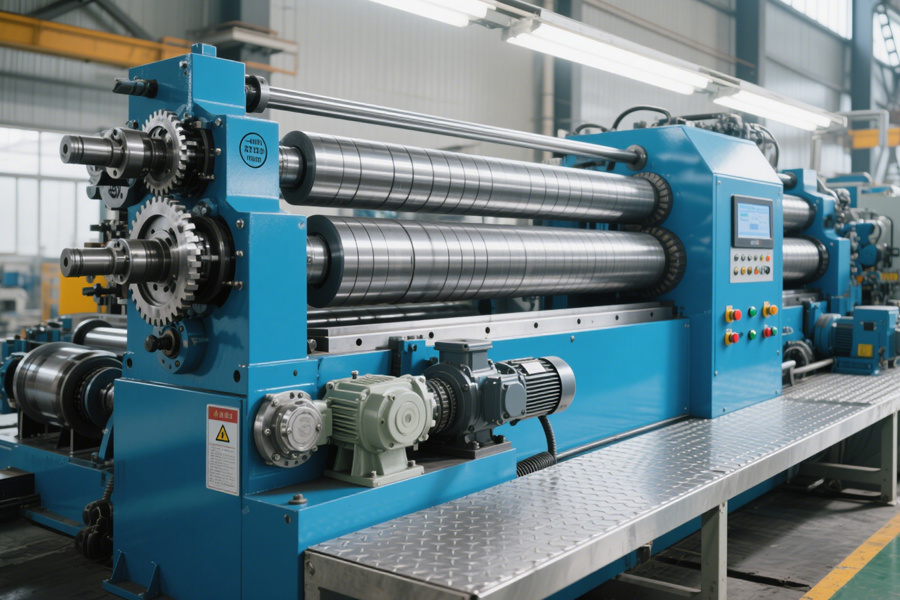

CCM key components (mold/segment/straightener)

The efficient operation of a continuous casting machine relies on the coordinated cooperation of various key components. The performance of these components directly affects the quality of the cast billets and production efficiency.

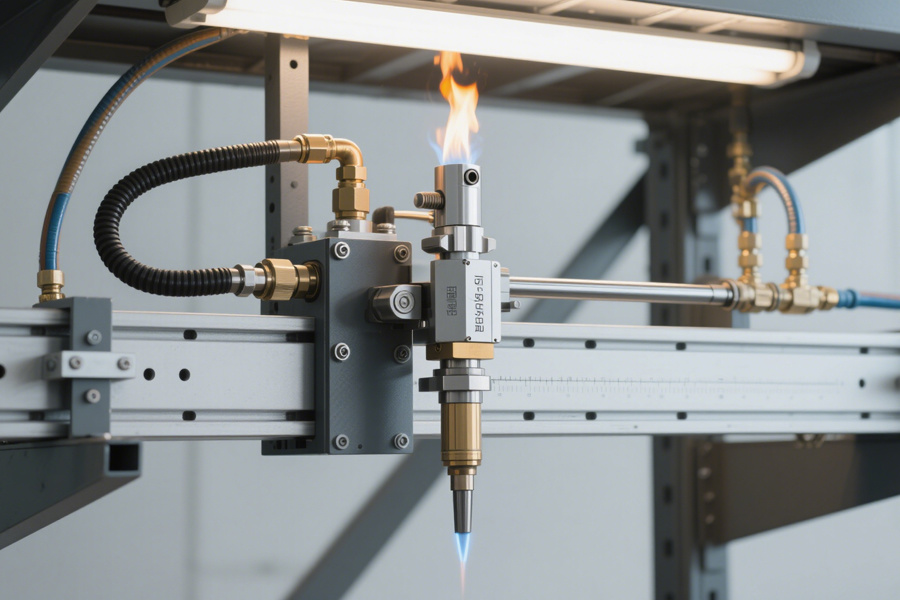

Continuous casting auxiliary components cover equipment such as cutting, deburring, conveying, and weighing. Flame/mechanical cutting devices achieve the fixed-length cutting of billets, deburring machines ensure end-face quality, conveying rollers connect the production process, and weighing devices accurately measure the weight, together forming a highly efficient auxiliary system for continuous casting production.